STA. MARIA, Isabela -- A ceramic water filter facility outfitted with high-performing equipment from the Department of Science and Technology (DOST)’s program for small businesses, dubbed SETUP or Small Enterprise Technology Upgrading Program, was blessed recently during the Cagayan Valley leg of DOST’s “Science Nation: Agham na Ramdam” nationwide roadshow.

SETUP offers assistance to micro, small and medium enterprises via funding, technology upgrade, and manpower training, to improve their production and product quality, and be at par with other small businesses in the regional and national levels.

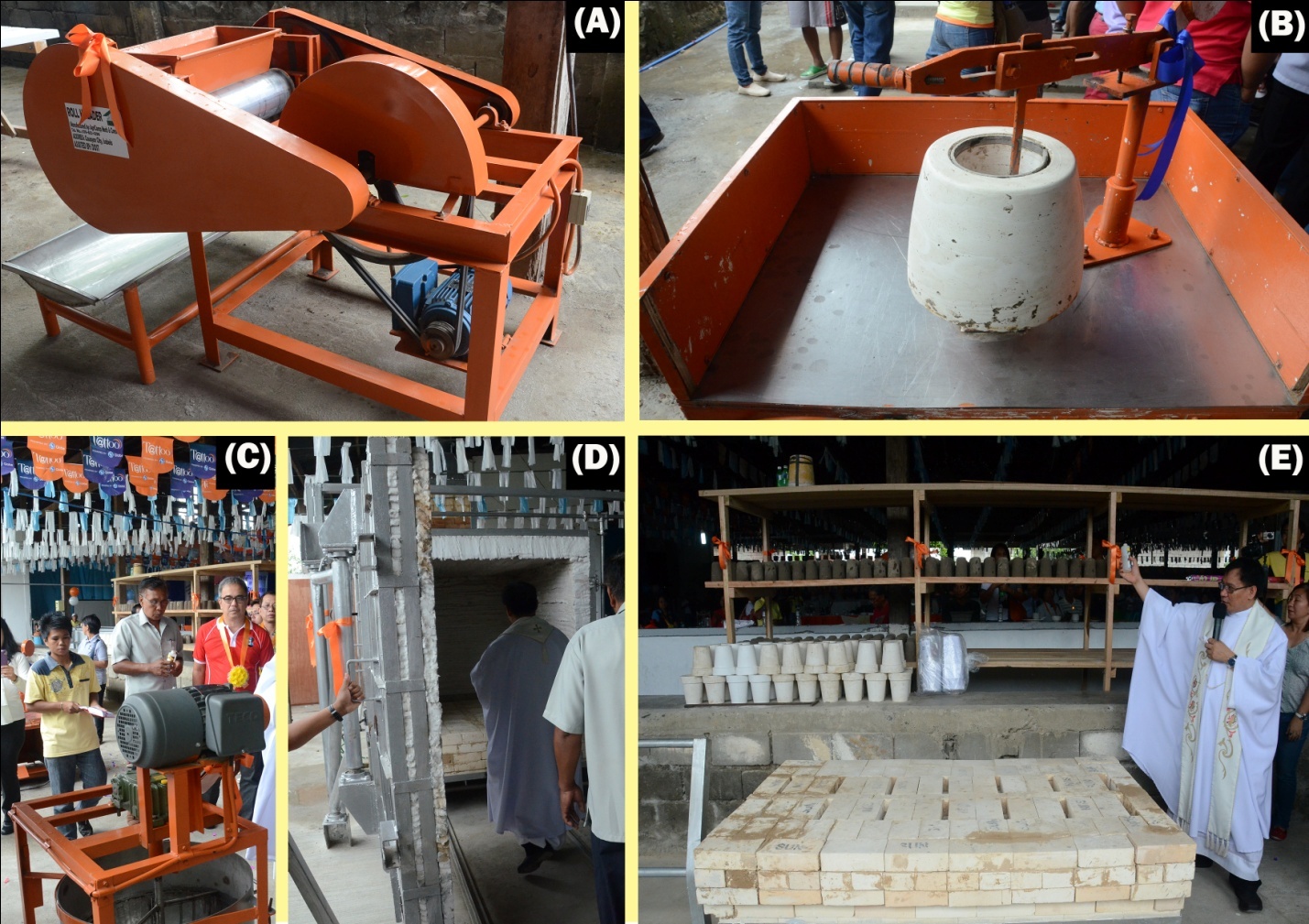

In 2013, the facility, which has been operating since 1977 (initially as a ceramic facility), acquired important machines via SETUP. Under the program, the DOST regional office’s testing laboratory may also be used by pottery enterprises and others for water and soil analysis.

SETUP provided assistance through the initiative of then newly elected Mayor Gilbert Masigan and the Sta. Maria Potters Association. This initiative was part of the campaign to secure clean drinking water for communities with less access to water.

Ceramic production goes high-tech

The ceramics used in the facility was found to have antimicrobial property, so it was upgraded to become a water filter facility. Likewise, the facility’s processes used to be done by hand, and these are now mechanized through the SETUP assistance.

The candle-type filter pot produced at the facility has two parts: a ceramic pot where untreated water passes, and a container that stores treated water.

“Our water filters are made from clay or ceramics, but we used advanced technology to produce them,” said DOST Secretary Mario G. Montejo during the blessing rites officiated by Rev. Carlos Villanueva.

During production, clay is mixed with water and other combustible materials. Water impurities like suspended particles are sifted because these cannot pass through the clay pores. Meanwhile, water that flows through the spaces in between the slightly-porous clay reacts with trapped silver ions. Silver ions deactivate and kill the pathogens in the water, including coliform bacteria and protozoa.

Better days for industry

The abundant red clay in the area has long served as raw material for ceramic and pottery production. From a neighborhood of around 30 households that made ceramics without electricity, there are now four barangays and around five families working for the pottery. The families in the area have practically grown up with this local industry that has been running in the community since the pre-war era.

The Sta. Maria Potters Association is among this bevy of potter makers in Isabela. Prior to SETUP intervention, association members faced negative net income due to low market demand for the clay pot products for ornamental purposes.

With the SETUP-assisted ceramic water filter facility however, things are expected to start looking up for them. Not only will the potters have a higher quality product that can fetch higher revenues; they will also be able to save on costs. Air drying, as opposed to oven drying, saves up on fuel and other costs, and reduces industrial pollution as well.

“At dumating na ang pagkakataon na itong ating ceramic ay mabibigyan ng isang booster, isang tulong na siya sigurong magpapalago sa kanya in the future (And now the time has come for our ceramic pottery to be given a booster which may allow the industry to grow and thrive in the coming years),” said Sta. Maria Vice Mayor Geoffrey T. Formoso.

For inquiries about SETUP and setting up a ceramic water filter facility, please contact or visit your nearest DOST regional office. (By HAZIEL MAY C. NATORILLA, S&T Media Service, DOT-STII)

INNOVATION SYSTEM SUPPORT. (A) Roll kneader, (B) Jiggering machine, (C) Clay mixer, (D) Shutter Ceramic kiln (2 cubic meters), and (E) Ceramic slabs (Photos by Gerardo Palad, S&T Media Service, DOST-STII)